Key Points

- Natural Language processing (NLP) can enable effective automation of many text processing tasks

- Industrial Maintenance activity generates a large amount of text data in the form of reports, plans, and schedules.

- Text data is extremely rich in information, but does not lend itself to large-scale review and analysis.

- NLP and text mining techniques are able to process large quantities of text data and present clear insights

- Smart application of NLP and other text processing can aid in the planning, execution, and documentation in a range of maintenance activities

Computer interpretation of text has made major advancements in recent years, but computers still cannot yet achieve human-level comprehension of text. Computers, however, are capable of analysing text significantly faster and in much larger volumes than humans. Using AI technology, insights can be extracted from text data that may have been missed previously. Within industry, maintenance activity presents a significant amount of language data in the form of schedules, historic records, reports, or scope spreadsheets. Ada Mode have implemented NLP techniques extensively to vast amounts of such maintenance data across multiple industrial settings.

Specific applications include:

- Predicting maintenance delays based on historic data of maintenance plans and known delays.

- Identifying historic problematic maintenance events from engineer feedback with sentiment analysis.

- Clustering of maintenance activities into related groups to leverage a richer set of historic information for use in informing future maintenance plans.

- Identifying candidate tasks that may be suitable for lower maintenance frequency to reduce maintenance bulk and de-risk outage periods.

- Alignment of maintenance plans from parallel systems across the fleet to obtain a more complete picture of component status.

The following sections will explore some of these applications in more detail.

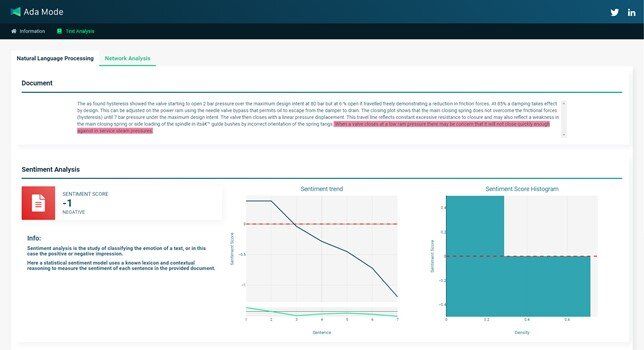

Inspection Report Assessment - Sentiment Analysis

Summary reports produced by engineers after the completion of a system inspection contain valuable information on the system’s health, performance and maintenance requirements. At a large industrial plant, many thousands of these reports can be generated per maintenance period. This volume of data can be a challenge for the planning and management team to process manually, and as such valuable insights can be overlooked.

Sentiment analysis techniques can classify the tone of phrases and documents within these reports. Rapid and automated detection of maintenance reports that suggest critical problems or concerns allows for the prioritisation of manual report assessment by experienced plant personnel.

Evidence Collection - Document Clustering

Clustering methods can be used to gather related maintenance tasks and combine historic reports to build up a complete picture of planned and historic maintenance. The outputs can be used to guide the improved planning and execution of maintenance activity using the lessons learned from all collected historic activity as reference and evidence.

Maintenance schedules of large industrial systems can grow to significant volumes that can become difficult to manage and require the dedication of focused maintenance management teams to wrangle. Intra-dependencies or relationships between maintenance tasks can be hidden or unclear without the presence of a robust and consistent index/labelling system.

By applying clustering techniques on such maintenance records and schedule databases these lost relationships can be revealed. Ada Mode have extensively applied this technique to lookup historic maintenance activities, aligning them with upcoming maintenance plans as reference material. The outputs of the historic maintenance search can validate the current plan or lead to the suggestion of changes or deferrals. For example, consider a routine inspection task on a certain subsystem, by automatically gathering all related historic maintenance on this piece of kit including previous inspection tasks it may be decided that this maintenance task may not be required due to sufficient recent outcomes.

Click here to see a case study of this methodology in action

Automatic filing - Document Classification

Instead of using the unsupervised methods used in the clustering approach, with document classification a supervised machine learning model is trained on labelled documents. A new unlabelled document can be classified to one of several classes depending on the scope of the application.

Ada Mode have experimented with this approach to solve many NLP tasks relating to maintenance data:

- Classifying if a maintenance record is of high importance or is present on a single point vulnerability system.

- Predicting the likelihood that a task may be deferred based on deferral behaviour across the fleet, helping to rapidly assess maintenance scope and highlight potential optimisations to engineering teams.

- Estimating missing information.

- Predicting the risk of a maintenance task failing or deviating from the plan, in a manner which may result in further damage to the component or significant delay to the planned maintenance schedule.

Maintenance Scope Comparison - Fuzzy Matching

It is often desirable to compare maintenance schedules, between outages and assets. Ada Mode clients often struggle with the challenges of tracking the differences and similarities between iterations of a work-in-progress maintenance plan. Or similarly, to directly compare to a previous historic maintenance schedule or a schedule from a twin in the fleet.

To address this, we developed and applied bespoke ‘fuzzy matching’ algorithms, which leverage similarity metrics specialised for language data combined with domain knowledge to match the scope of multiple twin station maintenance plans, even where there are differences in task naming conventions and plant configuration.

The outputs allow to the plant operators to compare maintenance scopes task by task, and draw on experience from outside their plant, obtaining bonus reference information previously only available to other members of the fleet.

Summary

By leveraging NLP techniques within the planning and documentation of maintenance activity it is possible to process huge volumes of text, far beyond the capabilities of any individual or team. The techniques can help guide priority and provide insights not easily obtainable by human perception such as the comparisons to other maintenance scopes and single tasks classification approaches. Text contains a rich source of information which is not readily classified, tracked and visualised. NLP technology allows this information to be harnessed at scale, unlocking significant value for industrial operators.